Inventory management is one of the most challenging tasks in supply chain management. It requires constant vigilance over stock level. It also requires planning the inventory supply in deference to demand forecasting.

A gap in this planning can lead to overstocking. This can be a nightmare for businesses.

Overstocking can have repercussions for the supply chain, warehousing, logistics, and marketing. Excess stock is a burden that can tie up storage space and capital. It can lead to unplanned expenses and losses.

In 2020, overstocking caused losses worth $626 billion for retail businesses globally.

In this article, we will understand the meaning of overstocking. We will also look at the common causes of overstocking and ways to prevent it.

What is Overstocking?

In simple terms, overstocking is when you have more inventory than you can sell. The term applies to both purchased and produced inventories. The excess stock sits in your warehouse. But, as there is no demand for the overstocked inventory, it occupies warehouse space indefinitely.

Inventory overstocking can occur in a variety of ways. Excess inventory can pile up little by little. This usually happens over several sales cycles. The company does not track its existing inventory. The unsold inventory piles up with new inventory. If the supply rate is consistent, this cycle continues resulting in a large overstock.

Sudden shifts in market trends, customer demand, or business practices can also result in overstocking. In such cases, excess stock quickly piles up. Before a company can recognise the shift, the supply chain has already overstocked the inventory.

Overstocking vs Stockpiling

People often confuse overstocking with stockpiling. In principle, both of these are quite similar. They both refer to a situation where the supply outweighs the demand. But, there are some key differences. Unlike overstocking, stockpiling is intentional.

Some companies intentionally overstock inventory for future demand. This practice is called stockpiling. Whereas overstocking refers to an unintentional surplus of inventory.

Companies practise stockpiling for a variety of reasons. It can be to reduce the risk of supply chain disruptions. Or to get better rates per unit based on purchase volume. Companies can also stockpile products to take advantage of price or demand fluctuations.

But, if the demand estimates are inaccurate, stockpiling can turn into overstocking.

7 Common Causes of Overstocking

Overstocking can stem from a variety of factors. It can be a result of poor forecasting, market shifts, supply chain issues, and so on. Sometimes major natural calamities or logistics disruptions can also cause overstocking. A clear example of this is the covid-19 pandemic.

Let’s understand some of the most common causes of overstocking.

1. Inaccurate Demand Forecast

Inaccuracies in demand forecasting are one of the top reasons for both overstocking and understocking. Businesses overstock expecting high demand for their products. But, these estimates do not match the actual outcome. This results in excess stock sitting in the warehouses.

Customer demand depends on a variety of variables. Incorrect estimates or inaccurate data on any of the variables can derail demand forecasts. These variables include historical sales data, consumer behaviour, market size, economic conditions, market trends, etc.

Furthermore, companies also need to account for the efficiency of their marketing channels to estimate consumer demand. When businesses overestimate the demand, it can result in overstocked inventory. The company then has to push marketing to clear the excess inventory.

2. Stock-out Panic

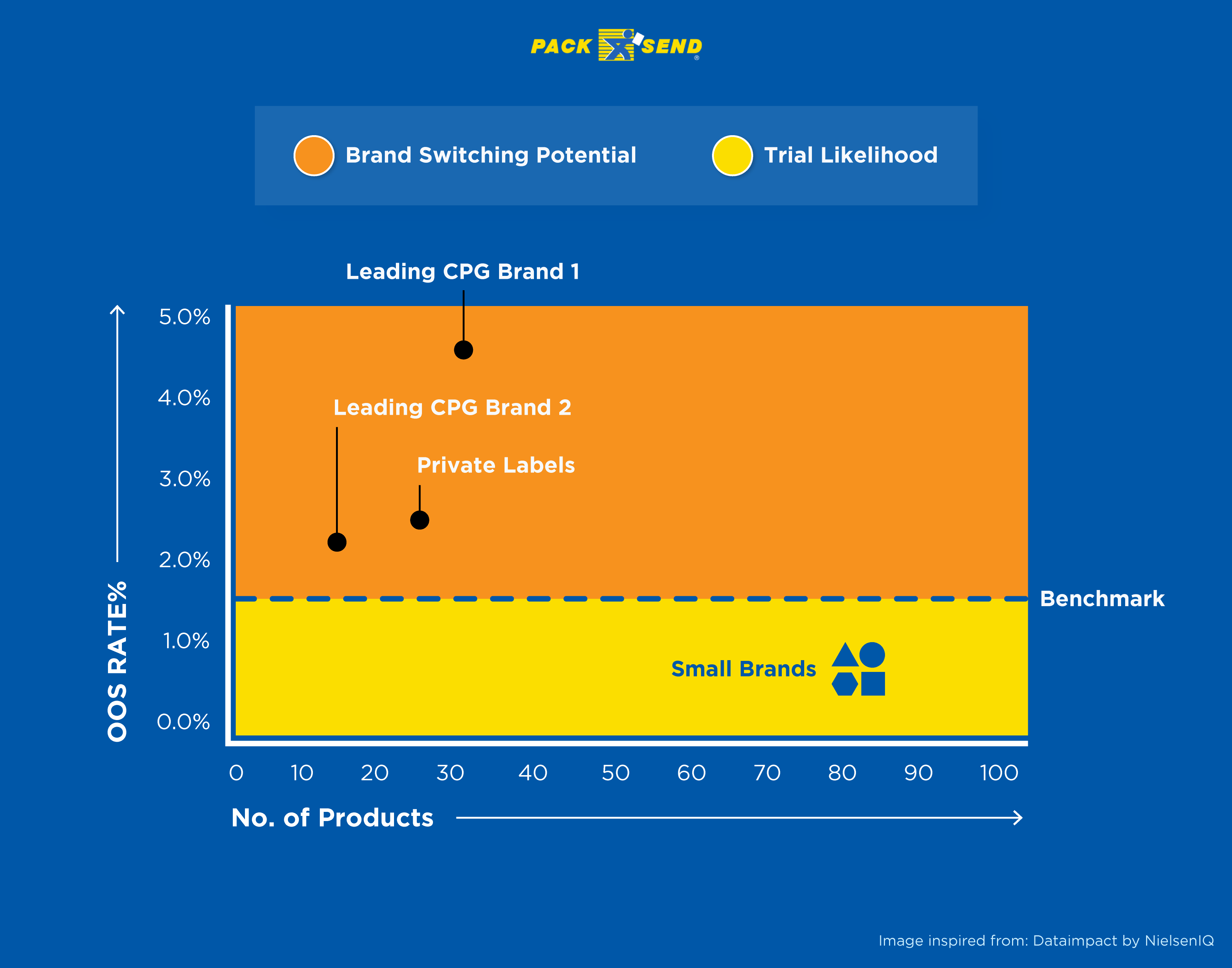

Stockouts can result in significant losses for a company. They can result in loss of sales, delayed order fulfilment, and poor customer experience. Companies can lose market share and customer loyalty.

On average, companies lose 3% of their profits annually due to out-of-stock items. Businesses justifiably fear stockouts.

This fear results in panic buying or production. For instance, a company sees a sudden surge in product demand. In fear of stockout, they purchase additional inventory. But, the demand falters and the company is left with excess stock. Such overcorrections against stockouts result in overstocking.

3. Inefficient Marketing

Businesses sometimes overestimate the effectiveness of their marketing campaigns. They end up overstocking inventory in hopes of generating demand through marketing. When these campaigns fail to deliver, businesses are stuck with overstocked inventory.

Marketing campaigns are a crucial part of demand generation. But, businesses also need to account for other variables that affect demand. You cannot assume that a captivating marketing campaign can sell out existing inventory. Over-reliance on marketing capabilities can often result in overstocking.

4. Inaccurate Inventory Management

Poor inventory management can lead to understocking as well as overstocking. 43% of businesses do not have automated inventory management systems. As a result, the average accuracy of stock visibility is only 63%.

If a company keeps ordering more inventory without auditing the existing stock, it can result in overstocking. This is because the company lacks visibility over its existing inventory levels. However, human error can also result in inaccurate inventory management.

Inventory management requires accurate information on the existing stock and demand forecast. It also requires an accurate estimation of inventory supply and order rate. This helps businesses estimate the inventory levels required to fulfil demand. If a company lacks data on these parameters, it can end up ordering more products than required.

5. Seasonality

Seasonal trends can have a huge impact on consumer behaviour. It can cause massive fluctuations in demand. Seasonal demands can affect both ends of the supply chain.

Companies often stock up on products in anticipation of high demand. This may result in raw material shortages and a surge in logistics charges. But, if the demand is less than anticipated, it can result in overstocking.

If the company cannot sell out the inventory during high-demand windows, it would end up with overstocked inventory. In such cases, the company has to invest in marketing, sell the products at low margins, or do both to clear the excess inventory.

Furthermore, certain products only have seasonal appeal. The company would have to store the overstocked inventory until the next demand surge. If the products are perishable, the company can face major losses.

6. Inconsistent Supply Chains

Businesses often overstock products for fear of supply chain inconsistencies or breakdowns. But, if they cannot generate enough demand for the stocked products, it can result in overstocking. The post covid era has seen several disruptions in the global supply chain. The pandemic, Ukraine War, the Suez Canal blockage, etc. had a major impact on supply chains around the world.

Companies stock large quantities to prevent stockouts owing to supply chain challenges. They might also overstock products to compensate for inconsistent supply from vendors or manufacturers.

Sometimes companies intentionally overstock inventory in anticipation of supply chain breakdowns. They intend to take advantage of shortages to sell products for better margins. But, when the demand does not surge, the company is left with excess stock.

7. Shifts in Market Trends

Companies end up with excess inventory if the market trends suddenly shift. This is more common in certain industries such as fashion, electronics, and F&B.

The company orders supply expecting consistent demand. But, consumer preferences suddenly change owing to a new trend. Consumer preferences can also change owing to news or geo-political events. This leaves the company with excess stock of old products that have little to no demand.

3 Predominant Impacts of Overstocked Inventory

Overstocking inventory can increase a company’s expenses. It may even cause the company to shift several strategic aspects of the business. This includes supply chain management, production, marketing, logistics, and so on.

Let’s look at some of the biggest impacts of overstocking.

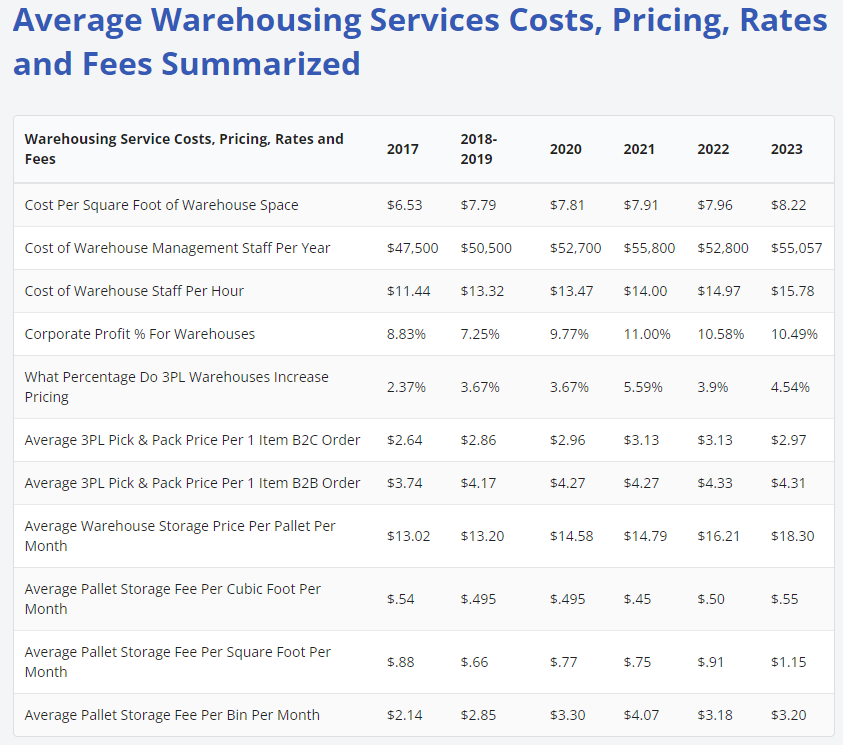

1. Additional Storage Costs

Storage costs are the most immediate impact of overstocking products. The excess inventory takes up the existing storage space. The unsold products eat away at the storage space of in-demand products.

The company has to alter supply chain strategies to compensate for the lack of storage space. Or they would have to purchase additional storage space to keep the supply chain running. Both cases increase the warehousing expenses. They not only pay for storage space but also for all related warehouse operations. This can diminish the profit margins of the company.

2. Capital Hold-ups

A company invests capital in purchasing or manufacturing inventory. They recover the investment as they sell the inventory. The overstocked inventory not only adds to the expenses but also holds up the investment.

When the company cannot sell the stocked inventory, it cannot recover its capital. This results in a capital shortage. The company then does not have funds to invest in new products that might sell.

They also need to push more money into marketing to clear the stock. This adds to the business expenses. Furthermore, the company may have to sell the products at competitive prices just to clear excess stocks. The added expenses and discounted prices can significantly cut down the return on investment. It may even result in losses.

3. Product Expiration

This is perhaps the worst outcome of overstocking. A company pours investment in gathering inventory. But, the products run past their expiration date in storage. This leaves the company with dead stock. The company cannot recover their investment from these products.

This applies to all types of products. Some products are physically perishable. They have a fixed expiration date. While some products have a trend-based expiration date. If the market trend shifts before you can sell the products, they will become obsolete. In this case, the product expires because there is no demand for it.

Such situations have a drastic effect on a company. Overstocking would have already raised expenses for the company. But, when excess inventory becomes dead stock, it results in major losses. To make matters worse, the company now has to bear expenses for disposing of excess stock.

5 Tactics to Avoid Overstocking

Overstocking can cause a lot of trouble for a company. But overcorrection against overstocking can lead to understocking. You need to balance your inventory levels to match customer demand. Here are a few ways to avoid overstocking.

1. Generate Accurate Demand Forecasts

Overstocking is the outcome of the gap between supply and demand. It often stems from inaccurate demand forecasting. So the best way to remedy excess stock is to generate accurate demand forecasts.

This requires analysis of different variables that affect purchase decisions. These would include market size, historic sales data, socioeconomic factors, brand perception, etc. You also need to account for market trends relevant to your products. A close analysis of current and upcoming trends will help you avoid overstocking unnecessary SKUs.

You also need to factor in the demand generated from your marketing channels. This is where many companies overestimate or underestimate the outcomes. As the marketing response depends on several variables. These factors concern the strength of the marketing campaigns as well as the customer’s behaviour.

You should run test campaigns on a small audience and analyse the results. This will help make more accurate predictions about the outcomes. You can then optimise your supply cycle based on demand forecasting.

This will ensure a balance between inventory supply and order fulfilment. So you will not have to bear the load of excess stock. Furthermore, accurate forecasting can also help you implement lean supply chain management strategies like just-in-time delivery and available-to-promise inventory management.

2. Using a Real-Time Inventory Tracking System

An inventory management system is a crucial tool to avoid overstocking and understocking. The software can give you real-time visibility of your inventory levels. This will help you plan the supply orders more efficiently.

An automated inventory tracking system helps you mitigate human error. Such errors account for 46% of problems in warehousing and inventory management. It can also help you significantly cut down warehouse management and labour costs.

An automated inventory management system will help you balance both supply and demand sides. You can catalogue received inventory in different warehouses. The inventory management system will automatically deduct SKUs based on orders.

You can also estimate inventory levels in the future based on the demand forecast. This will allow you to optimise your supply cycles and prevent excess stock.

Additionally, inventory management systems can generate analytics. These can help you identify the metrics. These can serve as KPIs for tracking the performance of different products. You can also calculate the storage and maintenance costs for different SKUs.

3. Calculate Optimal Inventory Levels

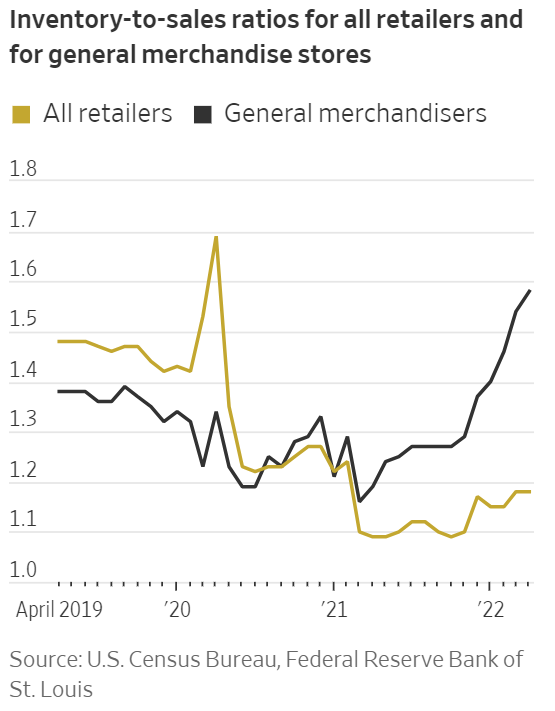

Optimal inventory level is the ideal quantity of products you should keep in your inventory. These levels are based on your supply cycles, demand forecast, and fulfilment rate. If you manage your inventory at optimal levels, you can avoid overstocking or understocking. This helps you control the inventory-to-sales ratio.

You need accurate data on several variables to calculate your optimal inventory levels. Inaccuracy can lead to stockouts or excess inventory. But, with optimal inventory levels, the excess stock will be in manageable quantities.

You can counter the inaccuracy by keeping safety stock. You can also define a marketing strategy for overstocked inventory. Maintaining optimal inventory levels will help you optimise storage, warehousing and distribution. You can run a lean supply chain at minimum stock levels.

4. Define Inventory Distribution Strategy

A logistics distribution strategy can help you prevent overstocking by dispersing the inventory in different locations. It also serves as a hedge against overstocked inventory. The distribution of inventory is based on product demand in different regions.

By distributing the inventory to different warehouses, you make space for new inventory. The distribution also brings the products closer to target markets. This can help you cut down on the logistics charges.

You do not need to own warehouses for logistics distribution. You can hire the services of a 3PL logistics company for this purpose. This allows you to use their logistics resources without bearing the cost of ownership. Furthermore, you only need to pay for the resources you use.

With logistics distribution, you are basically moving products from low-demand locations to high-demand fulfilment centres. This will help you clear out the excess stock faster and more cost-effectively.

5. Conduct Inventory Audits

Inventory management software can help you track and manage your stock. But, you still need to conduct inventory audits to analyse your strategies. These audits are especially necessary for businesses that overstock inventory frequently. You will track the effectiveness of your existing strategies and lay the groundwork for future planning.

You can involve several different criteria for inventory audits. These concern stock management, supply cycles, warehousing, order fulfilment, and so on. You need to gather data and track KPIs to analyse the performance of your inventory management strategy.

Some of the most important metrics to consider for inventory audits include:

- Cycle Time

- Inventory Turnover Rate

- Sell Through Rate

- Inventory Count

- Stockout Rate

- Fulfilment Rate

- Order Fulfilment Time

- Product Return Rate

- Time in Storage

- Inventory Carrying Cost

- Inventory to Sales Ratio

- Gross Margin Return on Investment

You need to track these KPIs for each SKU. This will help you identify the performance of different products. The inventory audit will also tell you how these products affect the supply chain. You will also identify the most frequently overstocked products.

You can define your inventory management strategy based on this audit. This audit will also help you plan for procurement, logistics distribution, and order fulfilment. Most importantly, you will learn how different SKUs contribute to your expenses and revenues.

A Logistics Partner Can Help You Avoid Overstocking

Overstocking represents a gap in supply chain processes and market demands. Businesses overstock inventory without forecasting demand. This leads to added expenses and supply chain disruptions.

You can prevent overstocking by optimising your inventory management process. This involves utilising your resources to strike a balance between incoming and outgoing inventory.

You can also partner with a reliable logistics company, like PACK & SEND, to carry out order fulfilment for you. Your logistics partner can store and manage your inventory. Furthermore, they can directly carry out order fulfilment.

This will save you from all logistics burden concerning storage and shipping. It will expand the scope of available resources to better distribute your inventory to target markets. As a result, you can prevent overstocking in one location.

Frequently Asked Questions (FAQs)

What are overstocking and understocking?

Overstocking and understocking are both measures of inventory against demand. Overstocking is when you have more inventory than demand. Understocking is when you have less inventory than demand.

Overstocking negatively affects the operational cost of a company. On the other hand, understocking negatively affects sales. A company should maintain optimal inventory levels to avoid both of these phenomena.

Is overstocking a good practice?

Overstocking is not a good practice as it leads to excessive inventory. This in turn increases storage and maintenance costs. Overstocking is not a business practice. It is a consequence of poor inventory management and demand forecast. It also puts pressure on the company’s supply chain and marketing operations. The excess stock can lead to diminished profit margins or outright losses.

What are the advantages of overstocking?

A company benefits from overstocking only if there are favourable shifts in market trends. If the supply of the overstocked inventory decreases in the market. Or if there is a sudden surge in demand for those products.

In such cases, the company is better positioned to fulfil the demand compared to the market. So they can sell out the overstock at better margins. Many companies intentionally overstock products for such opportunities. This practice is called stockpiling.

What are the disadvantages of overstocking?

The disadvantages of overstocking include excess storage costs, capital hold-ups, and dead stock. Excess inventory also holds up storage space which can disrupt the supply chain, logistics, and distribution. Companies that overstock inventory may have to invest more in marketing or sell at lower margins to clear the excess stock.

Why should you avoid overstocking?

Overstocking occupies storage space that could have been used for high-demand products. The lack of storage space can result in stockouts for in-demand products. The company also has to compensate for the lack of demand for overstock products. They would have to invest more in marketing and cut down profit margins to clear the excess inventory.

Image sources: Warehousing and Fulfillment, Abdalslam, WSJ,