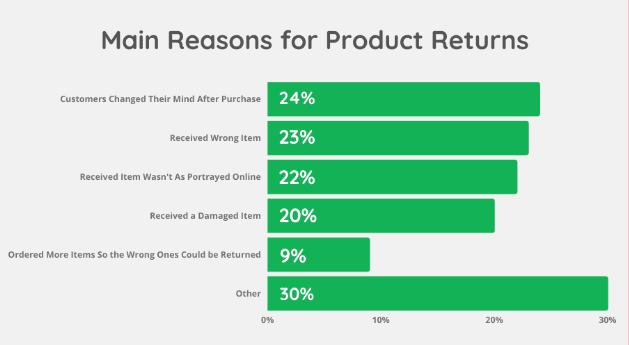

As eCommerce sales and order fulfilment rise around the world, so do mishaps. Many eCommerce companies face a rise in product returns. 30% of all products bought online are returned. Among these, shipping damages account for 20% of product returns.

A company has to bear additional expenses to replace damaged products. They also face the danger of losing a customer due to poor experience. Shipping damages also harm the brand’s reputation.

In this article, we will look at some of the common causes of damage during the shipping process. We will also understand the liabilities of different parties for damaged items. And we will share a few effective methods to prevent shipping damages. Let’s start with the causes.

8 Ways to Automate your eCommerce Business

A package changes hands several times before reaching the customer. Any of these exchanges can result in shipping damages. However, some common bad practices are often responsible for damaged goods. Let’s look at some of the most common causes of damage during shipping:

1. Flawed Packaging

Product packaging is one of the most common causes of eCommerce shipping damage. This is often caused by excess space in a package. The shipping process can be rough. Hence, the package experiences jerks and physical shocks. If there is empty space in the package, the product will tumble within the courier box. This can lead to damage during the shipping process.

Using flimsy material for packaging can be another reason for damaged goods. Products need adequate protection while shipping. Light-weight material can reduce the cost of shipping by a small margin. But, it compromises the durability of the package. This can lead to damaged delivery. The company has to bear a lot more expenses if the customer receives damaged products.

2. Insufficient Cushioning

Packages need cushioning to fill the empty space. Some items need cushioning material even if the package is size appropriate. The cushioning material absorbs physical shocks during storage and transportation. It helps protect the primary contents of a package.

You also need to consider the appropriate cushioning for the package. For example, if you use packing peanuts to cushion fragile loose parts in one box, it won’t provide the appropriate protection needed for contents. The parts can still move within the box and crash against one another. This can result in shipping damage regardless of the precautions.

3. Improper Labelling

Appropriate labelling is critical for eCommerce order fulfilment. The labels carry vital information. It tells the shipping carrier about the contents of the package. These include:

- Fragile contents

- Package orientation

- Storage instructions

- Handling instructions

- Hazmat warnings

If the package is not appropriately labelled it can lead to misjudged handling. This in turn can lead to damaged goods. For example, you are shipping delicate objects without a fragile label. In such cases, the carrier would not separate it from the rest of the packages. So the fragile item does not get the treatment it needs. This could lead to a damaged delivery.

Similarly, many products require special handling to prevent damage during the shipping process. The labels must carry the appropriate information to inform the carrier on how to treat a package.

4. Weather Conditions

Unsuitable weather or unfavourable storage conditions can also damage a shipment. The shipping label usually informs the carrier about ideal conditions for products. This information largely pertains to temperature and humidity. Ignoring these instructions can damage products during shipping.

These conditions have a greater impact on certain types of products. These include cosmetics, pharmaceuticals, food products, etc. If you are shipping products over a long distance, you need to account for changing weather conditions.

For example, you are shipping products from New South Wales to Queensland. These two regions have drastically different weather conditions. The average summer temperature in New South Wales is 5.7 °C. But, in Queensland, the average summer temperature is 30.8 °C.

If you do not account for such temperature changes, it can result in eCommerce shipping damage. For instance, the ideal temperature to store skincare products is 4°C to 15°C. If the environment is too hot, it can reduce the shelf life of the product.

If it is too cold, it can result in crystallisation of the contents. Either way, the customer will receive a damaged product if storage conditions are not appropriate during shipping. Weather conditions also have a significant impact on packaging. For example, corrugated boxes can get 71% weaker if humidity rises above 50%.

5. Human Error

Sometimes, it is merely human error that results in damage during the shipping process. Human error accounts for the majority of incidents in the shipping sector. Human error in handling, documentation, or packaging is a common cause of eCommerce shipping damages.

This error in judgement or an accident can happen at any stage. It can occur while organising inventory in the warehouse. It can also occur while picking products for order processing. Even accidents during last-mile delivery are considered a human error.

Who is Responsible for Shipping Damages?

The shipping carrier and the seller both hold responsibility in case of shipping damages. It depends on the cause of the damage.

For example, if poor handling led to damaged packages. Then the carrier is liable for a shipping damage claim. But, the seller would have to prove that the product was damaged during transit. This is quite difficult to trace. But, if flimsy cushioning led to damaged shipment. Then the seller is liable for shipping damage claims.

Regardless of the situation, most laws dictate that the seller is responsible for replacing damaged products. The Australian Competition and Consumer Commission (ACCC) has defined laws for this.

It states that businesses must pay for loss or damage that fails to meet consumer guarantees. It also outlines that businesses have to pay for damages that are reasonably foreseeable. ACCC states that the company does not have to pay for damages caused after a product left its control.

Facilitating returns is a costly affair for retailers. But, it is an essential part of customer satisfaction in eCommerce. 66% of online shoppers check the return policy before buying. Additionally, free returns have a huge impact on purchase decisions. 71% of online customers that return policy affect their buying decision.

This is why most retailers (49%) offer free returns. But, shipping damages can significantly affect a company’s bottom line. They have to replace a damaged product. They also have to complete the entire reverse logistics process for this. That is why most shipping carriers provide shipping damage insurance. The cost of replacing damaged products can be 17 times the cost of shipping.

The companies can make shipping damage claims to recover part of lost revenue. But, in most cases, sellers are left to their own devices to tackle shipping damage insurance claims. The best way to avoid losses is to prevent shipping damages.

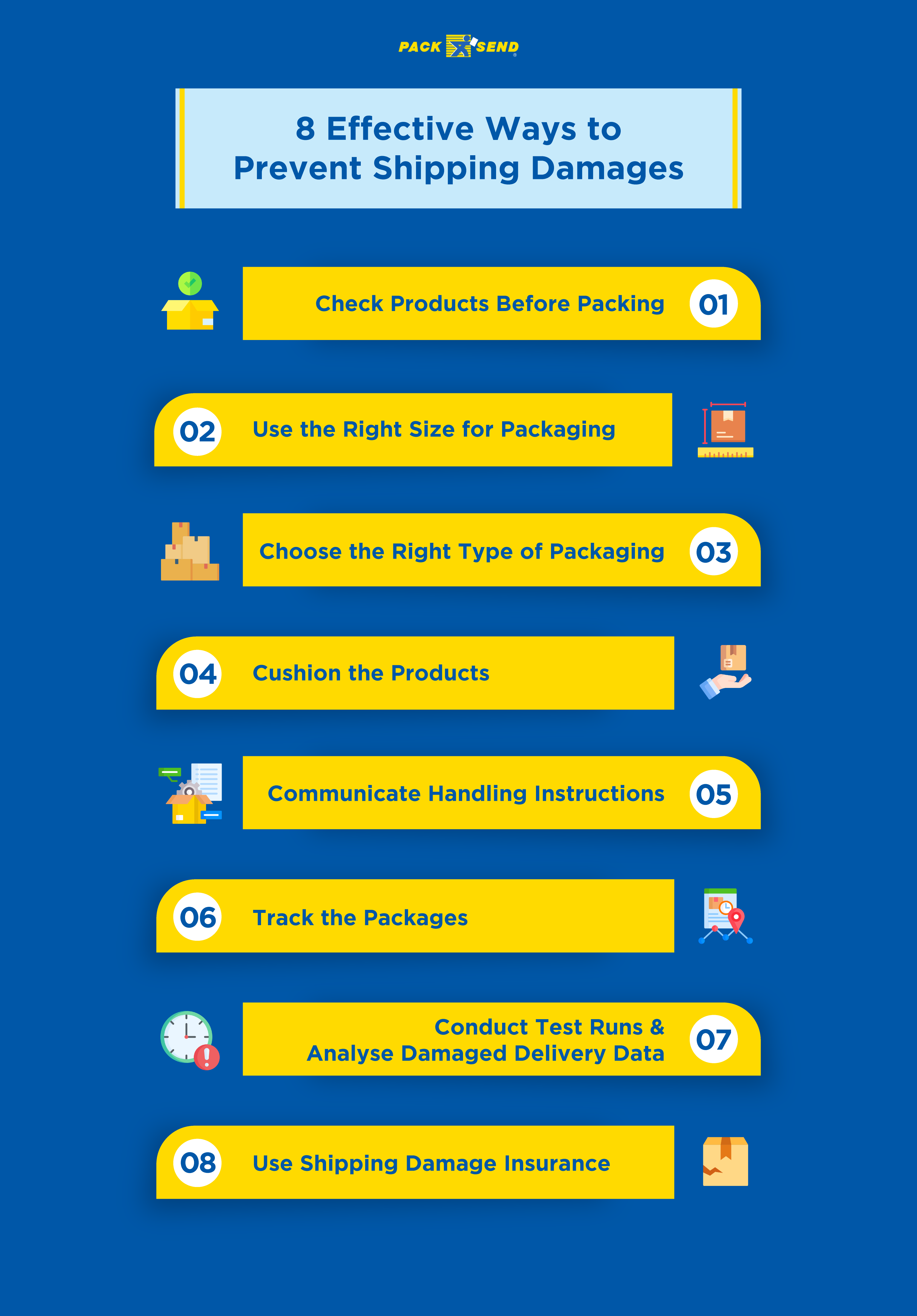

8 Effective Ways to Prevent Shipping Damages

Shipping damages can really harm a company’s revenue. It also impacts the brand reputation and customer satisfaction. Here are a few ways to prevent shipping damage during eCommerce order fulfilment:

1. Check Products Before Packing

This is the first step to prevent damaged products from reaching the customer. You need to check the products during order processing. This will ensure that you are not shipping damaged items. Sometimes you might unknowingly ship products that have minor damages. 11% of inventory at the distribution centres has some form of case damage. These get accentuated due to physical shocks during shipping.

You can conduct quality checks when picking and packaging products. This will help you reduce the instances of damaged delivery. Including this step in order fulfilment also strengthens your shipping damage insurance claim. You will have definitive proof that the product was damaged during the shipping process.

2. Use the Right Size for Packaging

The right kind of packaging can help you prevent eCommerce shipping damage. The right size of the box will tightly encompass the product. This will prevent the product from moving too much during shipping.

You need to consider the dimensions of your products to pick the right size. The right size will keep the product fixed in a position. This will help prevent shipping damages due to shakes and jerks. You will also use less packaging material. A tightly packed package will also help you reduce the volumetric weight. This can help you reduce packaging and shipping costs.

3. Choose the Right Type of Packaging

The packaging material plays an important role in preventing damage during the shipping process. The choice of material depends on two factors. These include the type of product and the shipping journey. If the shipping journey is long, you need sturdier packaging.

Based on these factors, you should choose the type of packaging for shipping. The package should suit the product. It should completely encompass the product. It should also offer ample protection to prevent shipping damage.

For example, if you are shipping temperature-sensitive products. Then you should choose insulated boxes. The boxes are layered to provide temperature protection to your products.

You also need to ensure that the packaging material is sturdy enough to withstand shocks during shipping. At the same time, you should not go overboard with the choice of material. Sturdier packages like wooden boxes also increase the weight of the courier. This will also increase the cost of shipping. You need to balance these two aspects to find the right type of package for your products.

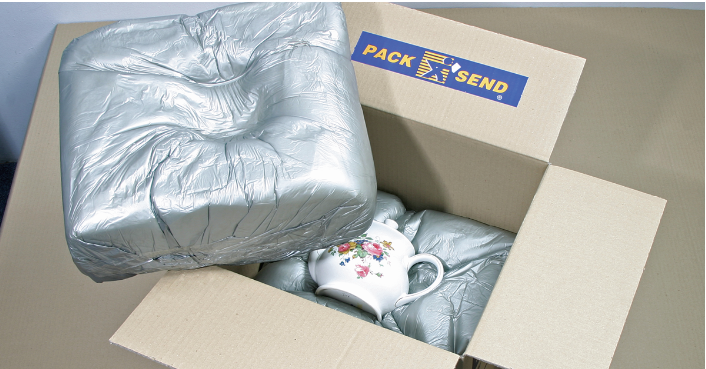

4. Cushion the Products

Cushioning is the final aspect of ensuring proper packaging to prevent shipping damages. Even with the right packaging the product can experience shocks during shipping. This is where cushioning material can help prevent shipping damage.

You can choose from a variety of materials to cushion your products. These include packing peanuts, bubble wraps, cardboard, wood shavings, paper threads, foam cushions, etc.

Cushioning serves two purposes. First, it keeps the products in place. Second, it absorbs physical shocks. This is especially necessary for delicate products.

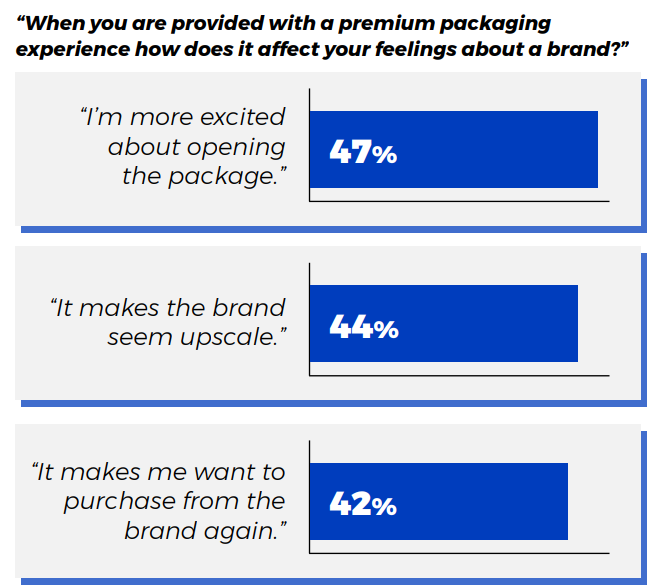

You also need to consider the aesthetics of your cushioning material. Appropriate cushioning can also create a more premium unboxing experience. This can help improve brand perception.

5. Communicate Handling Instructions

Some products require special handling during shipping. You need to communicate the handling requirements with the carrier to prevent shipping damage. So you need to use relevant labels on the package. Using the right labels can significantly reduce damaged delivery.

Some of the common shipping labels include:

- Hazmat Labels

- Fragile Labels

- Do Not Stack Label

- Keep Frozen Label

- This End Up Label

- Handle with Care Label

- Protect from Heat Label

- Keep Dry Label

- Refrigerate | Do Not Freeze Label

- Heavy | Lift with Care Label

You need to pick the relevant labels to convey handling requirements. You can also communicate storage requirements through labels. The labels should be large enough to grab attention. You also need to position the shipping labels for maximum visibility.

You can also creatively design the packaging to convey handling requirements. For instance, bike company Vanmoof faced 25% damaged shipments. So they redesigned the packaging. The new package showed a television set in the box.

This proved to be a successful strategy. The packaging changed the carrier’s perception towards the courier. This tactic helped Vanmoof cut down damaged delivery by 80%. You can also use creative designing to attract a carrier’s attention.

6. Track the Packages

You need to track the package throughout its journey. Shipment tracking may not directly help you reduce damaged products. But you can accurately map the journey of the product. You can identify potential hazards during the shipping process. Then you can rework your packaging to counter these hazards.

Shipment tracking serves as a form of vigilance. It adds accountability on the part of the carrier. You can also use labels or packaging with indicators. These indicators can track shocks, impacts, and tilting. They can help you track the cause of damaged products.

7. Conduct Test Runs & Analyse Damaged Delivery Data

Shipping damages can stem from a variety of reasons. Some of your couriers may reach the customer with damaged items. But, you need to act diligently if the number of damaged deliveries is unreasonably high.

You should record every instance of shipping damage. Then analyse the data to identify common occurrences. The data can help you estimate the cause of the damaged shipment. For example, if the majority of damaged delivery pertains to a certain delicate product. Then you should focus on optimising its packaging.

You can also use data to analyse if your implemented tactics are working. Analysing data can also help you identify the percentage change in eCommerce shipping damage claims.

You can also conduct test runs with different courier services. Then analyse their efficiency. You can count the instances of damaged goods with each company. This will help you identify the best shipping company for your eCommerce order fulfilment.

8. Use Shipping Damage Insurance

Most courier services would facilitate you with shipping damage insurance. You can claim insurance if your products are damaged during the shipping process. While this cannot prevent shipping damages. It does offer you coverage.

You must carefully analyse the terms of shipping damage insurance. You should ensure that it offers reasonable coverage for shipping damage claims. You should also check the compliance history of the insurance provider.

Reverse logistics can drive up your fulfilment expenses. An insurance claim can help you mitigate the losses to a certain extent.

Find a Reliable Logistics Partner to Prevent Shipping Damages

The majority of shipping damages stem from the irresponsible handling of packages. So the best way to prevent shipping damage is to hire a reliable courier service provider. An established shipping partner with trained handlers can ensure that your packages reach their destination without shipping damage.

This will help you cut down losses incurred from product returns. The shipping partner will also help you safeguard the brand reputation and customer experience.

Frequently Asked Questions (FAQs)

Who is responsible for shipping damages?

The responsibility for shipping damages depends on the situation. It depends on the stage when the damage occurred and who is responsible for that stage. If the carrier received faulty packaging, then the seller is responsible. If mishandling caused shipping damage then the carrier is responsible. However, it is the responsibility of the seller to replace damaged products.

How to prevent shipping damages?

You need to take several measures to prevent shipping damages. You need to ensure that the products are appropriately packed. You also need to communicate the necessary handling instructions with the carrier. Finally, you need to hire a reliable shipping company to deliver your products.

Can damaged goods be sold again?

You should not resell damaged goods. This can prove to be harmful to your business in several ways. First, you might lose a customer because of the poor experience. Second, it can damage your brand reputation. And third, you will have to compensate the customer for the damaged delivery. This is mandated by laws in several countries. Hence, you should not resell damaged products.

What sellers can do to minimise the cost of replacing damaged shipments?

Sellers can use a variety of reverse logistics strategies to minimise the cost of replacing damaged shipments. Sellers need to consider distribution logistics, packaging, and the location of warehouses to reduce the cost of reverse logistics. They need to develop protocols to handle various levels of damaged shipments. Sellers can negotiate blanket deals for fulfilment and reverse logistics with their shipping partners.

Which types of damage claims do insurance companies accept?

Shipping damage insurance companies operate on strict policies. The extent of the damage claim depends on the clauses defined in the policy. Broadly shipping claims have four categories: Damage, Shortage, Loss, and Concealed Damage. You need to check the insurance policy to check the extent of the shipping damage claim.

Image sources: Markinblog, Red Stag Fulfillment, Uline, Dotcom Distribution, Bicycling